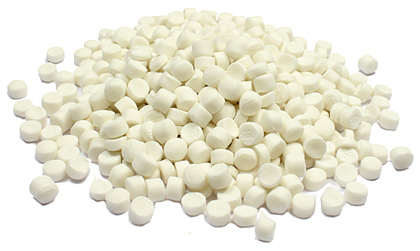

Overview Melos Compounds - based polymer & base rubber

The properties of the base materials in Melos compounds can be modified as required. Our products are precisely tailored to your requirements.

Basic polymers

Our kneaders produce granules / pellets from a large range of compounds. Basic polymers and rubbers include the following:

- EPDM - Ethylene propylene rubber

- SBR - Styrene butadiene rubber

- NBR - Nitrile rubber (Buna-N)

- NR - Natural rubber

- IIR - Butyl rubber

- BIIR - Bromobutyl rubber

- CR - Chloroprene rubber

- EAM - Ethylene acrylate rubber

- EVM - Ethylene vinyl acetate rubber

- PE - Polyethylene: HDPE, LDPE, LLDPE, VLDPE

- PP - Polypropylene

- EVA - Ethylene vinyl acetate copolymers

- Thermoplastics, polyolefin copolymers

- SBS, SEBS (styrene block copolymers)

- PIB – Polyisobutylene

- Others

Mineral fillers

Gently blending in large amounts of material is one of the strongpoints of our machines. We use a whole variety of mineral fillers to obtain the desired properties or cut costs.

- Chalk

- Talcum

- Barytes

- Kaolin

- Carbon black (grades with low to moderate reinforcement)

- Others

Plasticizers

The use of plasticizers is also essential when processing various rubber blends:

- Paraffin oils, including white oil

- Paraffin

- Polymer and phosphoric plasticizers

- Others

Additives

Many compounds naturally also require pigments, additives and other added materials to maintain their appearance and durability:

- Colours (as batch/pigment)

- Additives

- Processing aids

- and other added materials