We supply a variety of high-grade compounds as the base material for extruding and injection moulding rubber and thermoplastic materials. Individual formulations are realized economically and as specified by the customer: our production delivers what you need. This is illustrated by two firms which report on their experience with Melos compounds:

Zemo GmbH & Co. KG, manufacturer of open and closed-cell foam rubber

Zemo GmbH & Co. KG is Germany's leading manufacturer of open and closed-cell foam rubber panels or slabs for insulation, sealing and bedding. Located in Hörstel, North Rhine-Westphalia, the company has for many years collaborated with Melos GmbH to supply its own rubber formulations for use in producing semi-finished goods. The company was looking for a partner to supply a special EPDM blend, a so-called "master batch", for use in the production of Zemo EPDM foam rubber slabstock. A business partner recommended Melos GmbH on account of the latter's comprehensive experience in blending rubber formulations, as well as its technical expertise and the fact that it has the necessary production facilities. The company's proximity was a further advantage for Zemo, as it eliminated long delivery distances, storage requirements and complex logistics. "We have been working with Melos GmbH for a long time, for they know exactly what we need for our products and also appreciate the importance of unchanging quality in production. We require between 40 and 80 tonnes of pre-batch blend formulated according to our specifications every month. Above all, we profit from the development engineers and continuous quality management employed by Melos in its laboratories and production," says Wolfgang Parsch, managing director of Zemo GmbH & Co. KG.

Kronen-Hansa-Werk GmbH & Co. KG

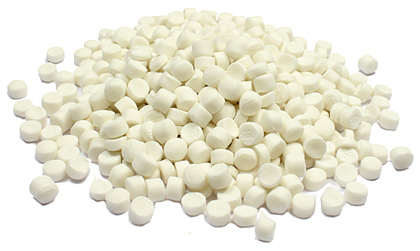

For more than 180 years, Kronen-Hansa-Werk GmbH & Co. KG in Lohne (Oldenburg), Lower Saxony, has been synonymous with high-quality tools and polymer products throughout Europe and Germany. The company has for several years collaborated with Melos GmbH in the field of "Customer Solutions". Kronen-Hansa was looking for a reliable, quality-conscious manufacturer of granulated material to supply between 200 and 300 tonnes per year for its special substructures for outdoor animal husbandry. "Our factory manager at the time recommended Melos. We need a raw material of unchanging quality for a customer product. In a number of test series, we were able to meet the specified requirements of the end product together with Melos. We achieved our objective of finding a raw material of unchanging quality for continuous, troublefree production in our factory. The closeness to Melos was a great advantage during the test series, as it also allowed an applications engineer from Melos to attend the sampling processes at short notice," says Sabine Borgerding, Purchasing Manager at Kronen-Hansa-Werk GmbH & Co. KG.